Walk-Thru: SeaDek

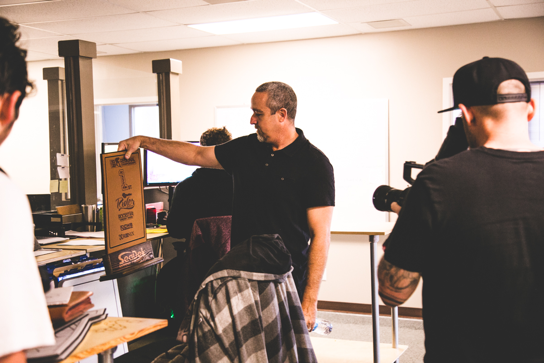

If you have stepped foot into a new wakeboard boat within the past couple years, then you know what SeaDek is. SeaDek revolutionized the interior boat game when they began manufacturing non-skid foam for the floor of boats. Gone are the days of taking out the carpet, so it doesn’t mildew when you put the cover on and gone are days of slipping and sliding and gone are days of hard textured fiberglass floors, all thanks to SeaDek. SeaDek invited us out to their headquarters in Rockledge, FL to see how it goes from a role of foam to the beautiful interior of your new and used boat. And as simple as that sounds, it’s actually quite impressive.

The process starts with giant rolls of colored foam that feature a patented foam and adhesive process. Next, colors are glued together to the specified color combination for the order. After the glue sets, the sheets are cut and transferred over to a precision CNC machine to have the logo and details etched into the foam. After the cutting is complete, the freshly cut pieces get separated by floor, swim platform and other miscellaneous pieces. They are then packaged and shipped to the boat manufacturer where they get installed within days of arriving. After touring the factory, it is evident why SeaDek is leading the charge in non-skid EVA products in the marine industry. The best part about this product is they don’t just make it for new boats. You can upgrade your old boat with custom cut SeaDek and make it look brand new again. If you don’t see your boat model on the website, contact your local SeaDek installer and they will come out and get your boat fitted for the season.

SeaDek

Rockledge, Florida

www.seadek.com